SPECIALISTS IN METAL SURFACE TREATMENTS+34 93 774 66 21+34 606 361 005

We carry out the complete degreasing of high precision metal parts and their preparation for subsequent treatments. We apply strict quality standards to all our services and processes.

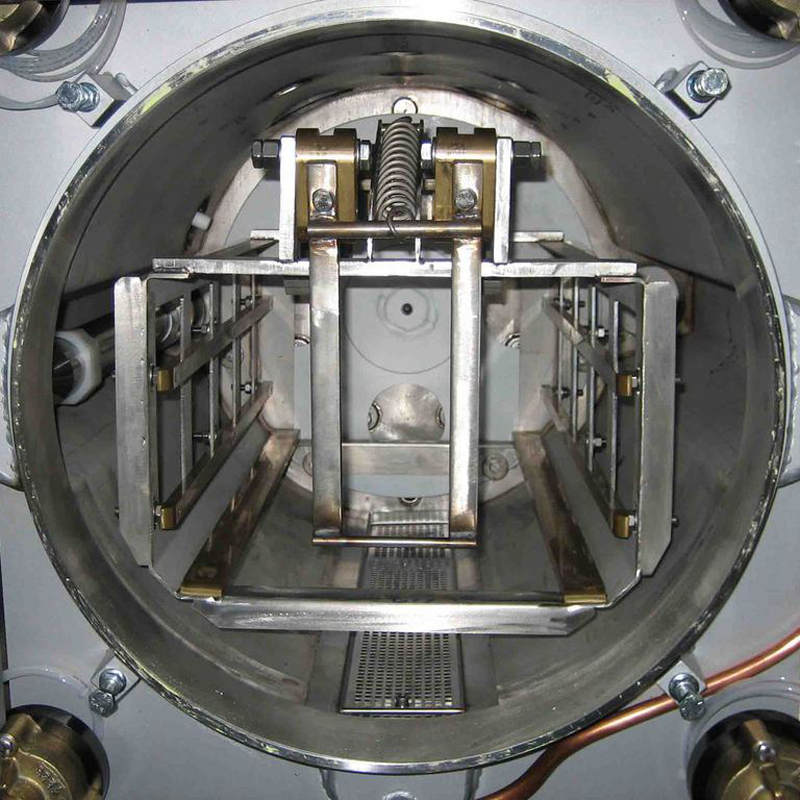

Thanks to the most modern technology, we eliminate any contaminant by means of perchlorethylene and its processes of steam, immersion, rotation, in static or adaptable baskets for very delicate pieces, thus ensuring the best results in terms of surface tension or basic degreasing needs.

This process is ideal for removing contaminants from all types of oils, etc. that cover the surface of the pieces, both metallic and non-metallic, before proceeding to their painting or any other subsequent process that the end customer has to do.

Our degreasing plant has a large production capacity to adjust to customer demands.

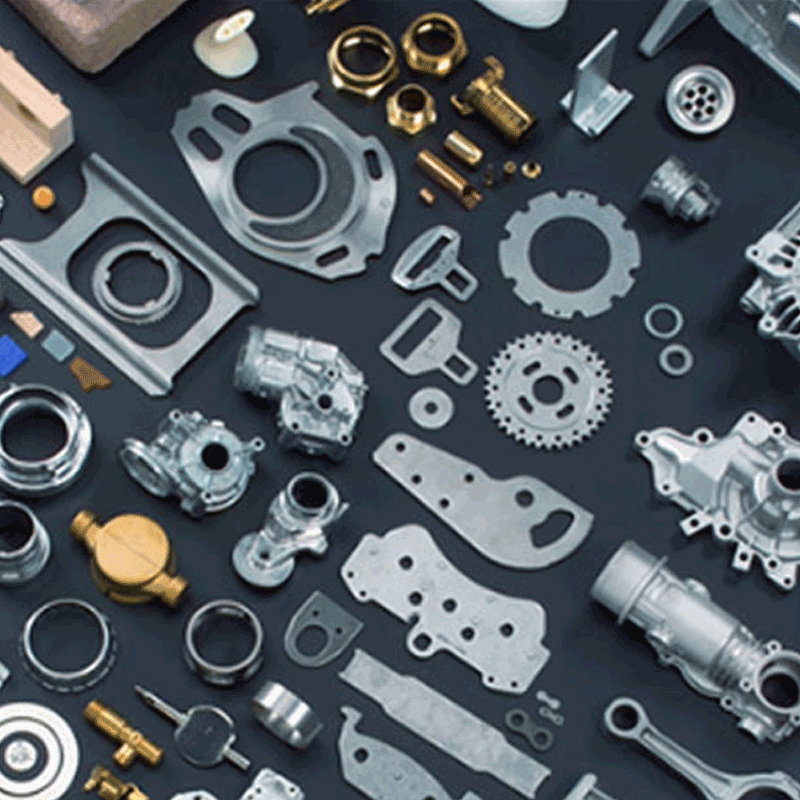

Technical Particle Cleaning consists of a very exhaustive and rigorous cleaning of parts, industrial components and products, which allows removing those metallic and non-metallic particles or fibers from the surface of the processed parts and components, which are not perceptible to the human eye (below 600 microns) but whose removal is necessary to meet some industry requirements according to own regulations, VDA19 or ISO.

The state-of-the-art water-based and ultrasound precision cleaning facility, in combination with the isolated rooms and controlled environment, achieves high levels of particle cleaning. A previous study, with the help of approved laboratories, helps us determine all the phases to take into account to meet the contamination requirements of the components.

The cleaning of particles in parts and products of sectors such as automotive, aeronautics, electronics for navigation systems, aerospace and sophisticated appliances, LED components, rail and naval sector, as well as products and parts of medical and laboratory technology: implants and prostheses, surgical instruments, etc. The cleaning of particles is required by the original manufacturers through their own standards for cleaning particles that must be met so that the components can be used in subsequent manufacturing and / or execution processes.

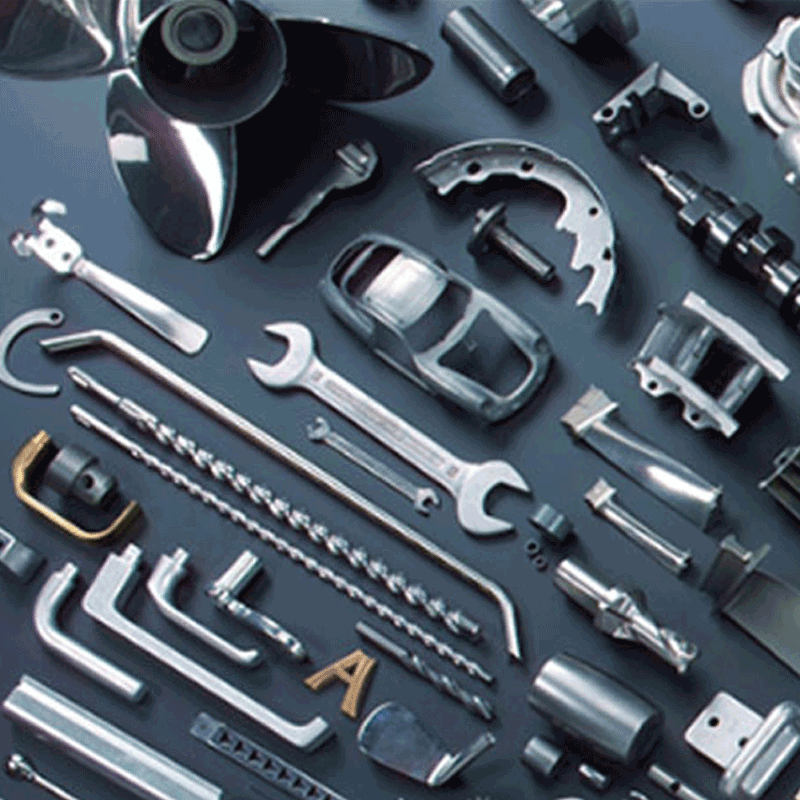

Blasting and sandblasting service with high precision machinery to obtain very high quality results in any type of material and shape of the pieces.

We carry out blasting processes for surface treatment by impact to obtain an excellent degree of cleanliness in each of the pieces.

Professional finishes in castings, forgings, bars, cables and plates. Shot blasting treatments for the preparation of parts for painting or other subsequent chemical and industrial processes.

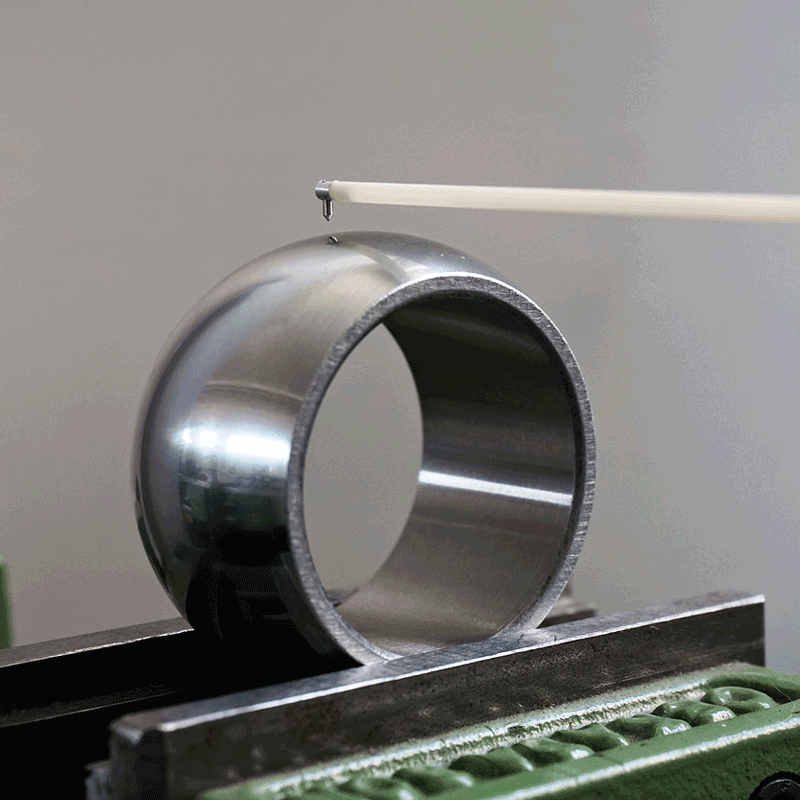

Specialists in polishing metal parts and micropolishing. We provide recognized results in the industry with the application of our work methodology, technique and strict quality control.

We polish pieces for any volume, material or design of the piece and apply different certified processes to obtain the optimal desired result.

We carry out blasting processes for the surface treatment by impact to obtain an excellent degree of cleanliness in each of the pieces.

Professional finishes in castings, forgings, bars, cables and plates. Shot blasting treatments for the preparation of parts for painting or other subsequent chemical and industrial processes.

Treatment of parts by this system to obtain a roughing by vibration with different types of abrasive materials and liquid or powder additives.

We have different types of vibrating machinery to obtain in each case the optimal results and Quality Control throughout the process.

We carry out the assembly of parts to prepare in the following own or external treatment processes. Preparation of parts for assembly lines and industrial automation.

We certify all our processes and treatments carried out, inspection, laboratory tests, monitoring, production, availability, verifications and Quality Control.

We provide extensive experience to all our clients with our team of highly qualified professionals who apply the latest technology and regulations in all our services.

Preparation of packaging and logistics management, shipments and supply cycles of parts for industrial production lines and workshops.

Certifications in all processes of entry, exit, process times and availability of parts. We provide all the necessary logistics including transport services in collection and delivery to our clients both nationally and internationally.